Change Language :

Wear-resistant polymer gears

From a single part to high-volume production

The gears made of the tribologically optimised iglidur high-performance polymers prove that a significantly longer service life is possible over gears made of commercially available plastics. Due to fine-tuned additives of reinforcement materials and solid lubricants, they do not require additional lubrication. Our plastic gears can be used in various applications.

Our product range

In our gear shop, you can purchase various types of plastic gears with no minimum order quantity. Here you will find spur gears, gear racks, bevel gears and angled gearboxes.

Spur gears

Number of teeth: 12 - 150

Module: 0.5 - 3

Gear racks

Module: 0.5 - 4

Length: 250 - 1,000mm

Bevel gears

Transmission ratio: 1:1 - 1:5

Module: 1 - 3.5

Angular gearbox

Transmission ratio: 1:1 - 1:5

Module: 1

Gears brochure and samples

Gears brochure

Our brochure provides an overview of our extensive product range and further information about our plastic gears.

Gears sample box

Our gear sample box contains gears, special gear racks, special parts and information on our plastic gears.

Gears sample bag

Our sample bag contains gears from our catalogue range and further information on our plastic gears.

Bevel gears sample bag

Our sample bag contains bevel gears from our catalogue range and further information on our plastic gears.

Gears checklist

Your personal application advice. Download the project checklist for your application advice now and fill it out conveniently on your PC.

White paper on gears: Design criteria for functional gear geometries

Find out which sources of error you should avoid and how practical solutions can make your designs more efficient and reliable.

The gears made of iglidur high-performance polymers enable lubrication-free and maintenance-free use.

Thanks to their special combination of base polymers, fibres, fillers and solid lubricants, they are extremely wear-resistant. Our gears have already successfully proven themselves in different applications.

The iglidur materials are put through their paces in our own test laboratory.

In accordance with the parameters in your application, we provide you with free advice on the right material and manufacturing and tool technology needed to make your individual gear (toothed component) in a reliable process without obligation.

You can place an order with igus without any minimum order quantity.

Our CAD database

Our CAD library makes work much easier for all designers.

Here you can create CAD models of our gears and gear racks, download them in various file formats and even transfer them directly to your CAD program.

No registration is required.

Gear test: cycles until gear break

Recording of the online seminar

Wear-resistant on four wheels - iglidur plastic gears in automotive applications

In this online seminar you will learn more about

- igus as an automotive supplier

- Your advantages through the use of the iglidur plastic gears

- Our manufacturing options - from prototypes to series production

- Real-world application examples

Our manufacturing processes

From a single part to several million

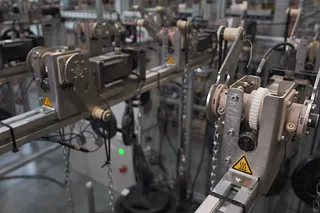

Application examples with polymer gears

That's why we developed gears:

iglidur® gears have proven their worth in different gearboxes and have also been tested under realistic conditions of use in the igus test laboratory. For example, torque fluctuations, efficiency and backlash of the gearboxes with polymer gears are electrically measured and evaluated. The gathered empirical values allow for continuous optimisation of our gears and use in wear-intensive continuous application.

iglidur® gears are characterised by their special wear resistance in use. Due to their special material composition of base polymers, fibres, fillers and solid lubricants, they have very low wear properties and do not require additional lubricants. This extends maintenance intervals and reduces expensive downtime minutes.

Your questions and our answers (FAQ)

What is a gear?

The gear is a round component with uniformly distributed teeth around its circumference. It is used to transmit power between two rotating gears or between a gear and a gear rack. Other types are used depending on the application.

What types of gears are there?

The most common types of gears/gearing components are

spur gearsgear racks* worm gears

bevel gears

Different kinds of gear and toothing are often combined with each other to produce certain motion sequences.

When do gears fit together?

For gears to move smoothly, it is important that the teeth can mesh with each other. To achieve this, the teeth of the gears must be the same size and therefore have the same module. This applies to all gearing components, e.g. also for gear racks, bevel gears, etc.

What is the module of a gear?

The module indicates the size of a gear. The module is calculated by dividing the pitch circle diameter by the number of teeth (m= d/z).

Please note that only gears with the same module can be combined.

How long does a gear last?

The service life of a gear depends on various factors. Firstly, which specification (e.g. module or number of teeth) the gear has and how the gear is used (e.g. application temperature, torque or speed). If you would like to know in advance how long a gear will last in your application, you are welcome to fill out our form for a free service life calculation.

Try it out now

How are the gears made from the iglidur® high-performance polymers?

At igus, gears are manufactured using three production processes:

- Injection moulding with iglidur® granules

- Mechanical processing from iglidur® bar stock

- 3D printing with iglidur® SLS or FDM materials

Depending on your enquiry, we will advise you free of charge and without obligation with regard to production in order to find the most economical solution together with you.

How are the iglidur® gears tested?

We have test rigs in our test laboratory to test our gear made from a wide range of iglidur® materials in various scenarios. We are also happy to provide you with samples for your application-related tests.

What is the minimum order quantity?

There is no minimum order quantity for our gears. You can request and order any quantity from 1 upwards.

Can the iglidur® gears be lubricated?

External lubrication of the gears is not necessary. All the materials we use are already tribologically optimised and designed for dry operation. However, if lubrication is required, this is possible in conjunction with a silicone-free lubricant.

I need a special type, is this possible?

Yes, the production of special geometries is possible and can be realised for all quantity scenarios thanks to our diverse manufacturing processes. We will be happy to advise you individually on your special geometry and the appropriate material. You can request your customised gear here.

What are the advantages of iglidur® gears?

The iglidur® gears require no external lubrication and are therefore maintenance-free. With our gears, you also benefit from a long service life thanks to wear-resistant materials, which we achieve through the formulations of the iglidur® materials. Compared to metal gears, plastic gears are quiet and offer optimum emergency running properties. The tribological optimisation of the materials also results in a low coefficient of friction.

When does a gear need to be replaced?

As soon as the gear is no longer able to transmit power due to wear, it must be replaced. By making geometric adjustments such as module, number of teeth or by selecting the right material, the service life of the gear can be increased.

What areas of application are there?

The iglidur® gears are used in all industries. Depending on the area of application, we offer special materials which, for example, are FDA-compliant or meet certain fire standards (e.g. the automotive sector) or similar.

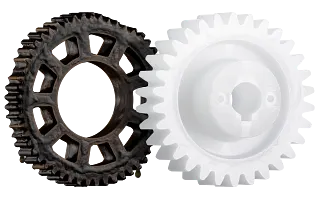

Polymer gear instead of metal gear

Tech up and cost down now

Plastic gears are cost-effective, require no external lubricants and are maintenance-free.

In contrast to metal gears, our plastic gears contain solid lubricants that reduce friction.

In addition, certain fillers provide an additional

improvement of the mechanical properties.

Advantages at a glance

- Lubrication-free

- Maintenance-free

- Lightweight

- Noise-reducing

- Corrosion-free

Further information on our materials

You might also be interested in

If you are looking for high-quality gearboxes that have been specially developed for your automation processes, our drygear gearboxes made of high-performance plastic are the ideal solution. These gearboxes contain wear-resistant plastic gears that ensure precise and reliable performance.

All igus plastic gearboxes are modular; they can be expanded as required and integrated into existing systems.

Consulting

I look forward to answering your questions

Hennlich doo Beograd+381 11 63 098 17Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr