While your order is being processed, you are kept up to date by means of updates or by e-mail. The status of your order thus remains transparent for you.

Your individual turned and milled parts can be made of any types of iglidur® bar stock . At any time, you can choose from the entire variety of iglidur® materials in order to make use of the best tribological properties for your component in your application.

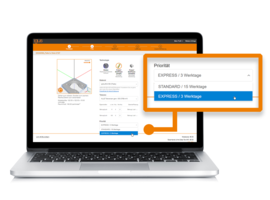

Indicate your desired throughput time. If our usual throughput time is sufficient for you, select "Standard". At an additional cost, you can prioritise your order if you need your order to be processed faster.

For the general tolerances of the parts with regard to length, shape and position, ISO 2768-m/K is applicable.

Different special tolerances for lengths are possible up to +/-0.05 mm

Holes can be configured as metric ISO threads or trapezoidal threads .Fits can be made in accordance with the ISO degrees of tolerance (IT) 10, 11, 12 and 13 in accordance with DIN ISO 286

Requirements outside of these standards are possible if a previous manufacturability test confirms this