Change Language :

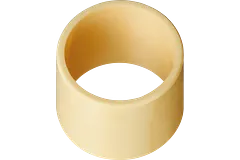

Plastic plain bearings for the mountain bike

Free sample box

Hold it in your hands in advance and see for yourself: Order the sample box with our top products for bicycles. It contains plain bearings made from various iglidur® materials, a gear, an igubal® rod end and a drylin® N linear rail.

Light, space-saving, vibration-dampening

No lubrication, no corrosion, no maintenance

Dirt and moisture have an adverse effect on metal bearings. In the case of PTFE-coated plain bearings, the gliding layer is quickly worn away after the ingress of dirt. Metal rolling bearings wear out quickly unless they are regularly maintained. In addition, cleaning the bike can be a problem for them if the jet of water hits the bearing point with too much pressure and flushes out the grease. The result is corrosion.* For iglidur plain bearings, dirt and moisture do not present a challenge thanks to the absence of lubricants. No external lubrication and no maintenance are needed here.

* This problem can also occur with bearings that are often referred to as "industrial bearings" in the bicycle industry. What is meant are non-adjustable metallic rolling bearings that are standardised and sealed.

Bearing points for dry-tech high-performance plastics on the E-Fully

More information

Consulting

I look forward to answering your questions

Hennlich doo Beograd+381 11 63 098 17Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr