Change Language :

Space-saving energy chain systems

Over 80 % less space required

energy chains are the most modular and probably the most compact form of energy supply, especially when energy, data, air and liquids have to be routed in one system. With over 200,000 e-chain® parts, we have the right energy supply for your installation space.

Realised in practice:

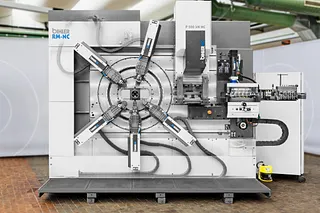

space-saving energy chain systems in stamping and forming machines from Otto Bihler Maschinenfabrik GmbH & Co. KG

With the RM-no camber and GRM-no camber machines, Otto Bihler Maschinenfabrik GmbH & Co. KG has developed the fastest servo stamping and forming machines in the world. The energy supply is provided by igus® energy chain and chainflex® cable. These systems offer a compact solution with limited space in the machine, flexible and safe energy supply in terms of manoeuvrability and length.

Recommended space-saving energy chain

Hundreds of thousands of customers rely on igus energy chains

Our energy chains are already reliably used in hundreds of thousands of applications worldwide - from beverage vending machines to steel mills. Over 400,000 customers worldwide from 50 industries rely on igus® energy chains.

You might also be interested in

Consulting

I look forward to answering your questions

Hennlich doo Beograd+381 11 63 098 17Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr